Manufacturing

Jacuzzi

Jacuzzi Mould the Future

Investment in Workforce Provides a Premium Return

Background

Bradford based Jacuzzi is a recognised market leader in the manufacture of kitchen sinks, taps and accessories for onward international sale, producing in excess of one million units per annum.

The Challenge

Jacuzzi defined their objective to improve manufacturing performance, increase customer satisfaction rates and provide a more reliable supply base, giving the company a highly valuable competitive edge. Incorporating and embedding a profound change in culture across the entire workforce was paramount for this to succeed following a period of restructure.

The Solution

Working directly alongside Jacuzzi, CQM Training & Consultancy Ltd created a tailored programme of Continuous Improvement learning and development that would unlock the potential skills base of Astracast’s existing workforce.

Working directly alongside Jacuzzi, CQM Training & Consultancy Ltd created a tailored programme of Continuous Improvement learning and development that would unlock the potential skills base of Astracast’s existing workforce.

Importantly for Rob Burrows, Jacuzzi’s CI & Manufacture Support Leader, the programme was underpinned by an accredited NVQ in Business Improvement Techniques further legitimising the training amongst employees and providing them with a real sense of achievement on completion of the programme. Jacuzzi have a strong commitment to workforce development and realising talent.

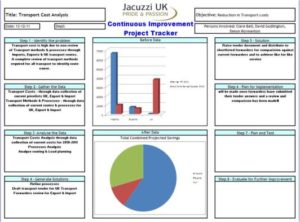

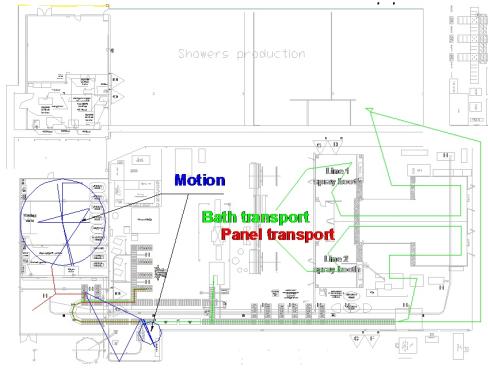

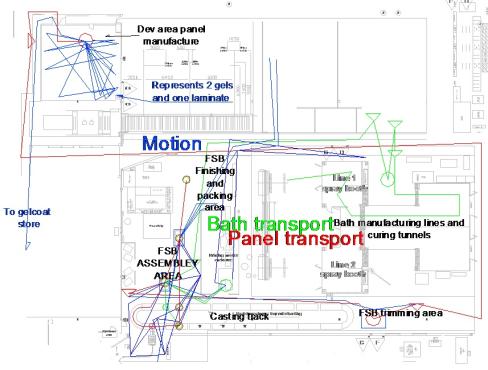

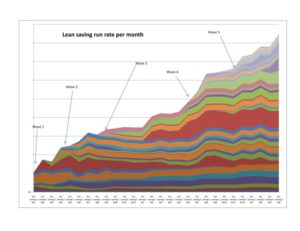

CQM T&C effectively led a succession of teams through 30 projects, each identifying and focusing upon the 8 Wastes of Manufacturing in their working environment. Resulting feedback revealed substantial savings in production, waste reduction, transportation and the efficient use of labour.

Shop floor workers took ownership of ideas, in particular applying 5S throughout their areas of operation, delivering an empowering change in culture. Improvement processes are now directly influenced and driven by those on the shop floor who consequently fully understand how small changes can make a big difference to bottom line savings.

Significantly, Senior Management became involved in the programme from the outset, actively leading workshops ensuring the adoption and acceptance of lean principles across the entire organisation from the Shop floor up.

Recognition of Success

- Excellent ROI in training with every £2 delivering a net return of £4

- Significant increase in profitability

- Huge increase in capacity

- Increased Competitiveness. Valuable new contracts won back from companies previously using Chinese manufacturers

- Improvement processes being driven from the bottom up.

- Empowered Shop floor owning ideas, effectively communicating with Management

- Breaking down of barriers between departments

- Positive change in morale

- Champions of Lean developed to continue the improvement process and sustain Value Added activities for prospective growth.

- 1/3 of the workforce successfully completing and awarded an NVQ

Why CQM Training and Consultancy?

With over 20 years experience of developing practical, performance enhancing solutions, Peter Booth, Managing Director of the successful Derbyshire based company explains, ‘Driving performance from the bottom up has definite financial and motivational rewards for both business and employees. Offering your existing workforce a structured programme of training and development ensures you maintain a valuable, experienced pool of skills combined with a committed management team who “discover” the skills of leading lean improvement cements the rewards in place.’

“I would like to roll out what I’ve learnt to other areas of the business which should have similar cost savings. I enjoyed the course and now have a better understanding of our business and how to reduce waste. I intend to continue improvement in the warehouse with other products”

“We appreciate the fact that we have achieved a new personal qualification in doing the NVQ course. The course has opened our eyes to how work and education can be used together and provides real benefits to both us and the company.”

“CQM T&C’s extensive approach to workforce development delivers a permanent change in culture which would not result from a quick fix solution or “college” type training. Sustaining and locking in improvements ensures a year on year return on investment.’ Rob continues ‘We are now winning back contracts from China, reducing lead times along with cost, whilst improving quality. Consequently customer satisfaction rates have dramatically risen.”