Manufacturing

Productivity Improvements at an extrusion factory

Case Study

This building supplies group extrudes sectional materials from a number of automatic lines. The company had a mixture of delivery and productivity issues.

CQM produced a Quality Cost Delivery Impact Diagram to assess the areas of factory under-performance and agreed the focus area with the operations management team.

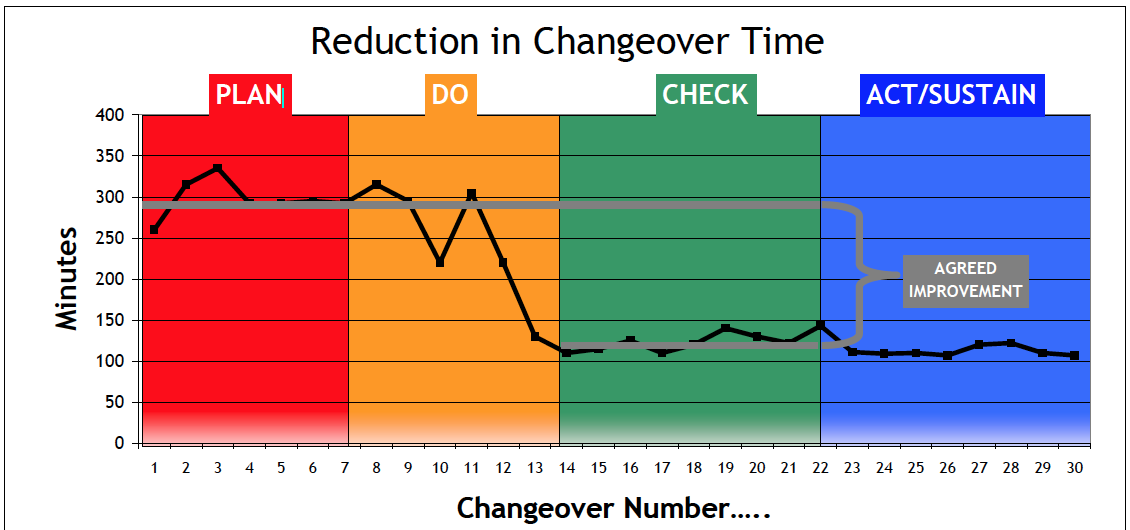

Key Identified Issues (PLAN)

- Poor line performance driven by long changeover times and poor performance after changeover

- Shift management solving shop floor issues – unable to take a long term view

- Significant safety issues caused by water running onto floor from leaks on extrusion machines.

Actions (DO)

Line Performance: Analysis of current changeover procedure leading to proposed changeover improvement. The team trialed and proved a split mother/daughter tool approach which also led to massively reduced manual handling

Management: Shop floor personnel tasked with making improvements for the first time : daily and weekly planning introduced

Safety: A zero tolerance approach introduced and the concept of 100 year fixes started. Workplace organisation au-dits and visual standards introduced for model cell.

Results (CHECK)

Changeover time decreased from 300 minutes to 123 minutes, leading to direct cost savings to the bottom line of £388,000 per annum through increased pro-ductivity. There were nominal costs for modifica-tions to tool racks and the change parts themselves.

Final Outcome (ACT & SUSTAIN)

CQM worked with the shift management team to standardise the new procedures and maintain the new level of workplace organisation. Outstanding operators were developed as line leaders and given the tools to drive every day CI.

Other Benefits

● Site senior management started policy deployment process shortly after this high impact programme

● Roll-out of Workplace Organisa-tion across shop floor leading to world class factory appearance

"CQM's Trainer had a really practical knowledge of implementation of Lean techniques. He engaged with all levels in the factory team to help them to create and own the 100 year fixes introduced."

Operations Manager,

Extrusion Company